The Clean Lithium Process

The alpha-En Corporation is an innovative clean technology company focused on enabling next generation battery technologies by developing and bringing to market pure, state of the art materials produced in an environmentally sustainable manner.

Coming soon: alpha-En’s pure lithium metal products.

BRINGING REVOLUTIONARY TECHNOLOGIES TO MARKET

alpha-En has developed the first process for the production of Lithium Metal using clean technology. Now the demand for Lithium Metal can be met without harming the environment.

alpha-En has developed the first process for the production of Lithium Metal using clean technology. Now the demand for Lithium Metal can be met without harming the environment.

The process for producing Lithium Metal currently in use has not changed significantly since 1891. The absence of advances in materials science, lackadaisical EPA regulations and moderate demand did little to incentivize producers of Lithium Metal to develop a new process. Alpha-En’s Chairman anticipated the increased demand for Lithium Metal and the market for energy storage decades ago. The goal was to help enable the advancement of new technologies by producing the necessary raw materials to sustain them, without harming the environment. His Scientific Research Team subsequently developed a revolutionary new process.

CLEAN TECHNOLOGY CUTTING COSTS

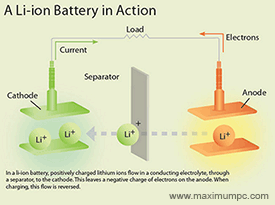

Reducing raw material costs is the key to profitability for battery companies.

Our novel process allows for production of Lithium Metal at a significant cost savings. The benefits of our process are noteworthy:

- Using Lithium Carbonate as feedstock reduces our raw material costs.

- Our room temperature process requires minimal electricity.

- Our process does not require mercury, again reducing raw material costs and eliminating containment costs.

- Our process does not release toxic chlorine gas, eliminating containment costs and associated environmental hazards.

- Our proprietary technology and the absence of many chemicals normally required yields an extremely pure product: lithium metal without nonconductive impurities.

Our Proprietary patented Room Temperature Process

alpha-En’s Process |

Traditional Process |

Produced at Room TemperatureProcess conducted at 20°-30°C. |

Produced at Very High TemperaturesRequires the electrolysis of molten salts at 400°-600°C (752°-1112°F). Process requires the burning of significantly more fossil fuels and adds substantially to the production cost. |

Process is Mercury FreeNo mercury is used in the production process. This reduces raw material costs, eliminates containment costs and the associated environmental risks involving the use of mercury. |

Production Process Requires MercuryThe process requires large amounts of mercury, which creates an unacceptable environmental risk and adds substantially to production costs. |

Chlorine Gas FreeUsing Lithium Carbonate as feedstock eliminates hazardous by-products such as chlorine gas which is released during the traditional production process. |

Requires Halide Salts of LithiumHalide salts release toxic chlorine gas during the lithium separation process. |

Uses Lithium Carbonate as FeedstockUsing Lithium Carbonate as feedstock creates a significant reduction in raw material costs and a myriad of environmental benefits. |

Uses Lithium Chloride as FeedstockLithium Chloride adds to raw material costs, and causes hazardous by-products such as chlorine gas which is released during the traditional production process. |